Tel:+86 757 83961118

Fax:+86 757 83960980

E-mail:fszdskf@126.com

Address:No.39 Jiangwan Foshan Guangdong

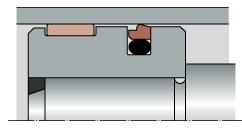

The basic demand on piston seals as well as on rod seals for hydraulic cylinders under the operating conditions for which they have been chosen, is to maintain a high level of sealing performance during their service life. The overall demands on both these function-determining main seals in the hydraulic cylinder are meanwhile very different in many respects. In this section, we feature both single- and double-acting piston seals.

The choice of the type of piston seal is to a great extent decided by the way in which the cylinder operates. For a cylinder which is exclusively single-acting, it is always best to choose the type of seal designed to provide optimum sealing qualities for single-acting functions, with, for instance, the thinnest possible lubrication film that can pass through the contact area between the seal and the cylinder tube surface.

The best sealing capacity of a double-acting cylinder is achieved by choosing a double-acting seal. A piston design where two single-acting seals on the piston for a double-acting cylinder are used can easily give rise to a breakdown. The reason is that a very high pressure can be trapped between the seals.

Piston seals, both single- and double-acting, can be designed for and used with integrated or separate back-up rings and guide rings. The ultimate choice must be based on the operating conditions of the cylinder.